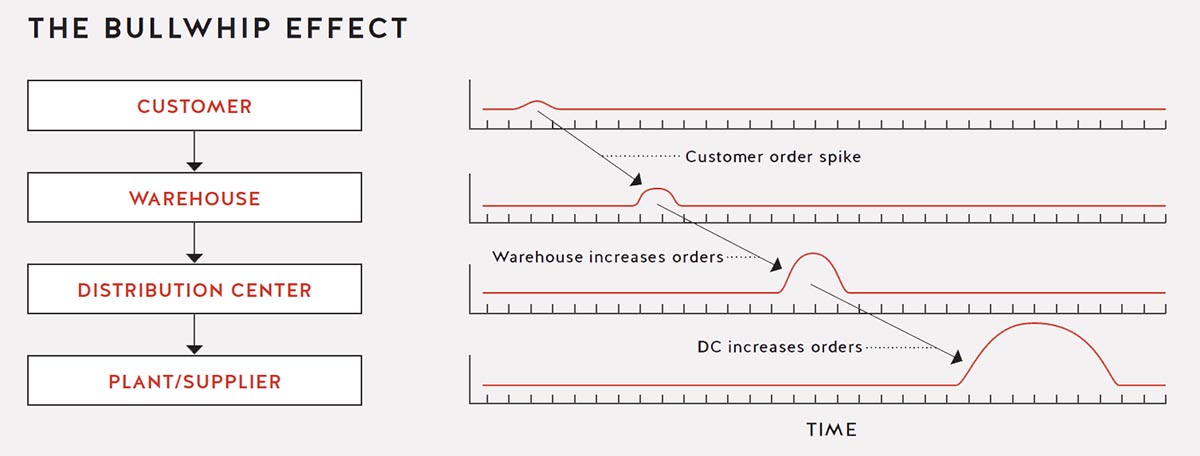

Only at MIT would students play a “Beer Game” to understand a supply chain phenomenon called the Bull Whip Effect. When you’re holding a whip, a small flick of the wrist creates ever-increasing amplitude down the length of the whip. It’s a problem food distributors deal with all the time because even the smallest variation in consumer demand can increase chaos and unpredictability upstream.

Jay Forrester, a professor at MIT from 1956 to 1989, devised the idea in the early 1960s to illustrate how supply chain forecasts can create inefficiencies. In the Beer Game, a single item — a case of beer — travels through a multilevel distribution system in a supply chain. Players operate four stages of the supply chain, and the objective is to order beer and deliver it to customers. Sounds simple, right? Not so fast. The simple act of a player changing the amount of beer ordered sends a ripple throughout the supply chain.

As consumers — the demand side — change their behavior, the supply side adapts inventory and warehousing activities. Players also blame each other for feedback failures that result in a lack of beer. But a build-up of supplies in a warehouse also reflects a communication breakdown between consumers and producers. You lose if you create a large inventory while trying to adjust to the change in orders. Product sitting in a warehouse costs money, so having a stable supply chain and deftly adapting to changes in demand is the winning play.

Research shows that a variation of as little as 5 percent can lead to a variation of 40 percent up the chain. For example, if consumers order fewer bottles of beer, the grocery store will send a message up the supply chain. (“Up” in supply chain lingo means moving from farm to the table; “down” means moving from table to the farm.) That 5 percent decline in beer sales in April could lead to inventory build-ups within the chain, over- ordering of packaging material, and misguided communication between brewers and ingredient producers and processors.

Another way this concept affects the food supply chain is when weather forecasters predict bad weather. A prediction of icy roads in Texas leads to a rush on grocery stores to purchase food while roads are clear. Store shelves empty, and the store’s procurement team returns to its inventory system to squeeze out more stock, while suppliers downstream scramble to find additional ingredients or sources.

As Beer Game players discover, one strategy for variation in consumer demand is to have extra inventory on hand so they can absorb a temporary uptick in demand. But storage costs money, and many food suppliers, intent on creating a “lean” supply chain, want to minimize inventory to save money and avoid food waste. Sometimes, when consumers stop buying a product, stores offer discounts and promotions, but that may cause unpredictable surges in sales that create more problems downstream. You can only hold onto tomatoes for so long.

Forecasts seem to be the culprit here, and the bullwhip effect is more about the problems in forecast-driven supply chain than in supply chain dynamics in general. If your supply chain depends less on forecasts and is more aligned with actual consumer behavior, the bullwhip effect may be dampened. Food companies that link point-of-sales data and supply chain planning can tighten the loop between consumer behavior and other activities throughout the supply chain.

If nothing else, the Bull Whip and the Beer Game reveal the systems effect of the food supply chain. Everything is connected, and one failure has dire consequences. Lack of beer is just one of them.

Author

Food+City publisher Robyn Metcalfe has been an editor and writer at Sunset Magazine, a heritage pig farmer and a food historian. You can find her @foodmiracle on Twitter because she thinks food is a miracle.