The second installment in our series about food bots focuses on tech in use in the cold chain. (Check out Part 1.) It’s not hard to see why robots would be ideal workers within these climate-controlled facilities, where temps often hover just above freezing for most perishable goods. Unlike humans, robots don’t get cold — at least, not yet.

Grocery Getter Bots

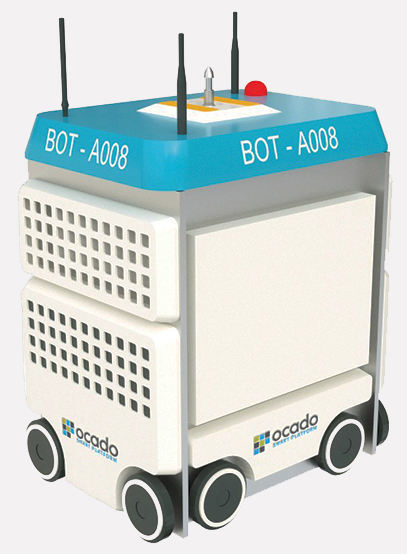

Some of the newest bot tech involves what are sometimes called swarms and the hive mind — as in dozens of robots working together (the swarm) to complete complex tasks, wirelessly sharing information in real time (the hive mind). Such is the case with Ocado Smart Platform robots, created by Ocado, a British online grocery retailer that’s working on making their delivery-only business as automated as possible.

Ocado’s squat, square, battery-operated bots zip about on an elevated grid over room-temp or refrigerated crates stacked several levels high. Each crate is filled with one specific type of grocery, such as eggs, organic apple juice or cheddar cheese. The robots work as a team to deliver the crates to “personal shoppers” — mainly humans, though another kind of robot could also do the job — that put together customer orders. If the hive mind sees one shopper needs cheddar, but it’s in a crate beneath the eggs and the apple juice, one robot zips by to move the egg crate, a second moves the juice and a third grabs the cheese and takes it to the proper shopper…all in a matter of seconds.

Thanks to the hive mind, every robot knows where every product is at all times; the robots are also tasked with refilling the tower of crates — aka “the storage hive” — as crates empty. Plus, when the bots themselves are low on charge, they ferry themselves off to a charging bay before rejoining their swarm.

Ocado’s bots zip around a grid built over crates and crates of groceries. They pick their orders and deliver them to humans, who do the final packing.

The bots work together, like a hive mind, to uncover buried crates and access items on lower levels. Their real-time communication also indicates which crates need to be refilled.

The system of robots — which can travel 13 feet per second — can fulfill a 50-item order in less than five minutes.

The stacked grid concept came from the shipping industry, where cranes move containers from place to place.

See these bots in action:

Super PaQ Bots

Palletizing robots might not sound revolutionary — palletizing being the unsexy term for the unsexy process of loading and unloading boxes on and off a pallet — unless you’ve worked in a frigid warehouse. Supplies come in on pallets, and products go out on them, and not always neatly: If a mini-mart orders four cases of sliced turkey, a case of chips and two dozen packs of hot dogs from its supplier, somebody or something there has to put all those boxes together.

Palletizing robots are generally “articulated arm” robots, which means they have a stationary base attached to a robotic arm that can bend and swivel. Hand-like tools attached to the end perform specific tasks — in this case, lifting and moving boxes from one place to another.

A company called Swisslog — they design fully automated warehouses and distribution systems — even makes a palletizing robot called RowPaq that can build a perfect pallet of mismatched boxes in minutes. It’s fitted with a set of giant hand-like grippers that can pick up four different sized boxes at the same time and set them down in a perfect row because it already “knows” how tall, wide and long each box is before it arrives.

Whether in a hot warehouse or a cold refrigerated facility, RowPaq can mix and match cartons, shrink-wrapped or foil-wrapped packages onto a single, stable pallet — up to 1,000 units per hour. It’s the ultimate Jenga player.

See RowPaq in action:

The Well-Below-Zero Bots

Think of the freezer as the final frontier for robotic solutions in the cold chain. Super-cold, sub-zero conditions — as in minus 18 degrees Fahrenheit — are just as hard on the moving parts and lubricants inside robots as they are on people.

The easiest solution is to put your robot in a protective suit, which is why when you do see the rare robot in a freezer, it’s usually sheathed in puffy white sleeves that look like a cross between a wind sock and a lab coat.

Most robots used in freezer conditions are large, sturdy palletizing machines with fewer small moving parts, such as bots used to stack table-sized slabs of frozen fish on a pallet. Other companies use spider-like “pick and place” robots to pack things including frozen meat patties and fish sticks into the proper plastic packaging. These bots are usually mounted over a conveyor belt, and the entire process takes place within a sealed, protective, temperature-controlled enclosure.

Author

Rachael Wharton is a James Beard Foundation Journalism Award-winning freelance food writer and journalist with a master’s degree in food studies from New York University. Her work has appeared in many publications, including The New York Times, The Wall Street Journal, Saveur, NewYorker.com, Lucky Peach and six cookbooks and counting.