Startup Spotlight: Vinder

Founded in Port Townsend, Washington, by Sam Lillie, Vinder connects home veggie gardeners with folks who want to buy that fresh produce. The app brings together community members who are interested in ultra-local food and reducing food waste. It also boosts the local economy by opening up a revenue stream for green thumbs who connect with their neighbors to share their garden’s bounty. We recently reached out to the 2018 Food+City Challenge Prize contestant to find out how things are going at Vinder.

What’s your founding date?

January 21, 2018.

How big is your team?

Four full time.

What problem are you solving?

Food waste, cost and food insecurity.

What’s been the biggest surprise about running your business?

As much as I heard and read about it, the investor “run-around” has been my biggest surprise. Most professional investors I’ve had the privilege to speak with don’t give a solid “no.” They give advice and information, which is great because it helps hone the pitch and business plan/strategy. But it may not be the right type of advice that works for your company or be useful when approaching other investors. It ends up being a massive time/energy zap.

What part of the food system are you in?

Vinder is situated in the distribution of hyper-local produce — neighbor to neighbor. Yet, we do not own any delivery vehicles or own any inventory.

What was the big idea that got you started?

My community, Port Townsend, Washington, had a big problem accessing local organic produce for a reasonable price. Vinder was created not to be some massive, disruptive company, but to solve a problem in my community.

Whom are you competing with?

For convenience, we compete with HEB or Whole Foods. For freshness and locality, we compete with farmers’ markets. However, we see ourselves as a tool to help those small vendors reach more customers and increase sales direct-to-consumer.

The coolest food system innovation I’ve heard of is…

a company called Vinder that allows you to buy, sell or trade homegrown produce and neighbor-made goods directly from your neighbors. It’s free to sign up and free to sell or trade.

The scariest thing about today’s food system is…

we have normalized an absence of connection to our food system. We have no idea what is actually going into the soil in which our food is being grown (or what chemicals are being sprayed on them), who is growing it or where exactly it is being grown.

What’s your latest big news?

We are now a user-owned and -operated company. After successfully closing an Equity Crowdfunding round of more than $85,000 via WeFunder and receiving matching angel investments, Vinder issued preferred shares to users who are taking a stand against our current food system and are opting to create the neighbor-made food system of the future. Vinder is also now available for iOS and Android.

Best advice you’ve received?

In the words of entrepreneur and venture capitalist Paul Graham, “Focus on getting 100 people to love you rather than 1,000 people to kind of like you.”

What advice do you give to potential startup founders?

You don’t need a lot of money to start a company. First, come up with the lowest-budget minimum viable product and validate that the market needs your solution. Then build out manually, followed by tech. Let tech be a solution to make a process more efficient rather than the primary focus.

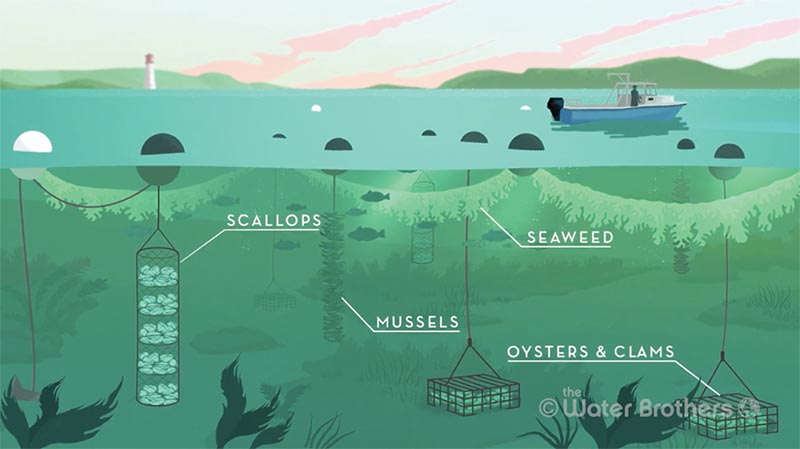

Merroir

Merroir

For delicious scallop pics and shots of the sea farmers at work, follow

For delicious scallop pics and shots of the sea farmers at work, follow

Keep up with the latest in logistics entrepreneurship and follow Layla Shaikley on Twitter

Keep up with the latest in logistics entrepreneurship and follow Layla Shaikley on Twitter

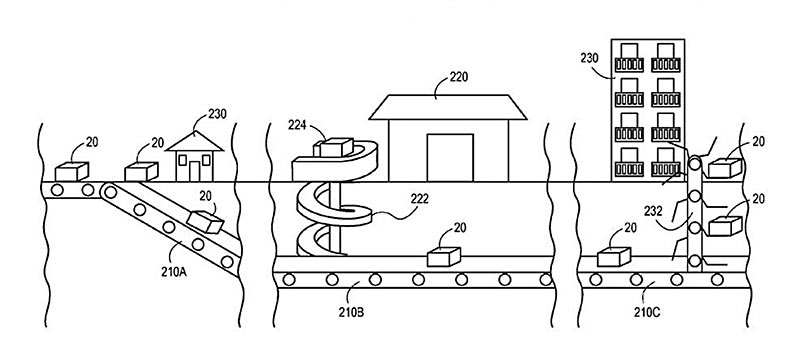

Don’t be surprised when you begin to notice your sidewalk cluttered with electronics instead of people. DoorDash, an on-demand food delivery service based in San Francisco, is testing out robots as an addition to its food-delivery workforce. [Read more about DoorDash in our story, “

Don’t be surprised when you begin to notice your sidewalk cluttered with electronics instead of people. DoorDash, an on-demand food delivery service based in San Francisco, is testing out robots as an addition to its food-delivery workforce. [Read more about DoorDash in our story, “