Best Before… Who Knows?

Real food. It’s what everyone wants — farm fresh and chemical free. But real food spoils. In the field, on the truck, at the store and in your fridge. That’s why innovators and entrepreneurs are coming up with new and nifty ways to help prolong the life of food.

The next time you purchase perfectly heart-shaped strawberries on the East Coast, consider this: They were probably picked and packed into their plastic clamshells on a Central Valley farm in California between five and eight days ago.

They could have been harvested on a balmy 70-degree morning or in the 95-degree heat of mid-afternoon. Perhaps they sat in the field for one hour — or four. Maybe the pallets took five days to cross the country in a temperature-controlled trailer, or maybe the trailer refrigerator broke down halfway through the journey. Once at the store, the strawberries might have sat on the shelf for a day, or a few more. “Many things can impact shelf life,” says Kevin Payne, vice president of marketing at Zest Labs, a San Jose-based tech company trying to take the mystery out of produce shelf life. “But you can’t see those until the very end,” when 24 hours later, your picture-perfect ruby strawberries morph into camo-green fuzz balls.

Six dollars wasted. Dreams of strawberry shortcake vanished.

And now you can add that pound of trashed berries to the 400 pounds of food you personally waste each year. According to the Natural Resources Defense Council (NRDC), 40 percent of food produced for human consumption in the United States goes uneaten. Just one-third of that wasted food could feed the 48 million Americans living in food-insecure households.

Wasted food is bad for humanity, but experts believe it could be even worse for the earth. Food waste is responsible for 16 percent of our country’s methane emissions — the pollution equivalent of driving 37 million cars per year. Growing, processing, transporting and disposing of food uses roughly 10 percent of the U.S.’ energy budget, 50 percent of our land and 80 percent of our fresh water consumption. So, when you figure 40 percent of that goes unused, that’s a lot of unnecessary pollution accelerating climate change.

In the developing world, most food waste occurs in the field or in transit due to poor infrastructure or lack of refrigeration. But in the U.S. and the rest of the developed world, the majority of food is wasted on the farm, at the supermarket and at home.

The food industry had mostly resigned itself to these inefficiencies. “The approach has been that waste is the cost of doing business,” Payne says. “And the solutions have historically been reactive.”

That’s all starting to change thanks to a shift in food culture, environmental awareness, technological advances and a host of entrepreneurs shaking up the industry through food-shelf-life innovations.

Polluting the Planet

Wasted food is bad for humanity, but experts believe it could be even worse for the earth. Food waste is responsible for 16 percent of our country’s methane emissions — the pollution equivalent of driving 37 million cars per year. Growing, processing, transporting and disposing food uses roughly 10 percent of the U.S.’s energy budget, 50 percent of our land and 80 percent of our fresh water consumption. So when you figure 40 percent of that goes unused, that’s a lot of unnecessary pollution accelerating global warming and climate change.

Protective skin

Searching for ways to prolong a food’s shelf life is nothing new. Humans have been salting fish, meats and cheese for thousands of years. We’ve created techniques like smoking, pickling, waxing and, more recently, adding chemical preservatives or ozone, to prevent spoilage. Today, delicate greens are packaged in Modified Atmosphere Packaging (MAPs) to replace most of the oxygen in the bag with carbon dioxide (a gas that slows spoilage). What’s more, refrigeration technology, which many experts agree is the key to extending shelf life, continues to grow more efficient.

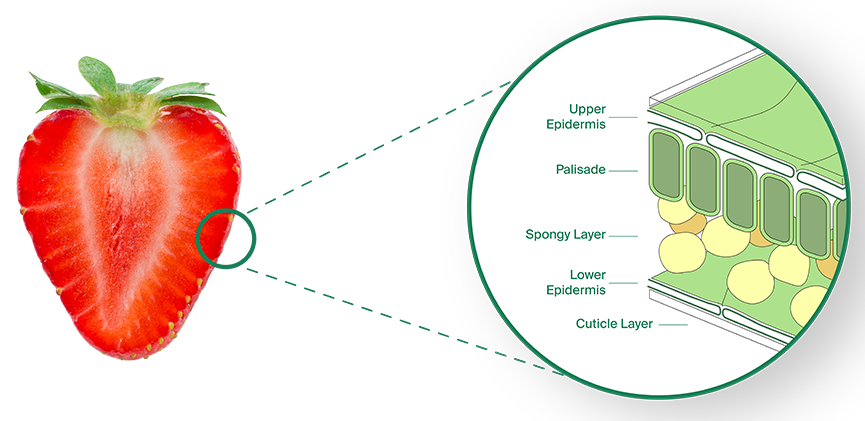

Yet some of the industry’s most impressive technologies — canning, freezing and pasteurization — were developed nearly 200 years ago. Fresh produce, which is wasted more than any category of edible food, is in higher demand now than ever. People want cleaner food — food that’s safe, with few ingredients and very little processing. Therefore, we need to find alternative ways to slow down the basic life process known as respiration. Food respires after it’s harvested, which means it consumes oxygen and gives off CO2, heat and water. If you slow a plant’s respiration rate, you can extend its shelf life. If you extend shelf life, you can reduce food waste.

Apeel’s product coats fruits and vegetables, slowing water loss and oxidation — two key factors in spoilage. The coating is made from edible plant materials and reinforces the protection provided by a fruit or vegetable’s natural skin. The diagram shows the microscopic layers of a strawberry’s skin. Image courtesy Apeel Sciences.

“Most solutions today have been focused on the transport period” of harvested produce, says James Rogers, founder and CEO of Apeel Sciences, a San Diego-based company that developed an imperceptible, tasteless and organically derived second-skin for produce. “We have controlled-atmosphere shipping, refrigeration, high-humidity storage — all of these are kind of solving the key things that cause produce to spoil, which are water loss and oxidation.”

Slowing food spoilage during transit is important, but Rogers wanted to protect produce through all stages of the supply chain, especially on the farm and at the grocery store.

“If you look at some of the most successful companies of our era, they’re using resources that were not being optimally utilized,” Rogers says, referring to Uber and Lyft for ride sharing and Airbnb for house sharing. “We can use technology to unlock some of that wasted value to improve efficiency.”

That’s what Rogers did when in 2012 he launched Apeel Sciences. The idea came to him while driving through California’s lush Central Valley, listening to a radio program about the one billion people who are hungry on this planet. He wondered why, when there was such an abundance of food growing around him, was one third of that food being wasted. With his knowledge of material sciences as a Ph.D. student and grants from the Bill & Melinda Gates Foundation and The Rockefeller Foundation, he began experimenting with ways to improve the shelf life of African cassavas, mangoes and bananas without using costly and environmentally unfriendly refrigeration.

To do this, he looked to organic materials left over on farms — grape skins, stems, leaves, etc. He and his team of scientists blended the matter up and extracted fats and specific food molecules. When these molecules are transformed into powder and combined with water, the resulting liquid can be rinsed over produce at wholesale produce-sorting facilities to create an undetectable “second skin.”

“We’re trying to use food waste to solve the food-waste problem,” Rogers says. The added “peel” acts to “physically slow down the rate at which water evaporates out of the produce and the rate at which oxygen gets into the produce,” he explains. “By doing that, we can dramatically extend the shelf life of most types of fruits and vegetables even without the use of refrigeration.” This science led to a Series B $33 million investment in the company, with big grocers like Kroger and Costco buying Apeel-treated produce to reduce their food waste.

Spicy Solution

Another entrepreneur using food to save food is Kavita Shukla, founder and CEO of The FreshGlow Co., which developed a natural paper infused with organic spices and active botanicals that when placed near produce can double — sometimes quadruple — its shelf life.

The idea came to Shukla when she was 12 years old, visiting her grandmother in Bhopal, India. Her mother had warned her not to drink the water, but she forgot while brushing her teeth. Her grandmother quickly mixed up a spice elixir for her to drink. Shukla never got sick. When she got home, she began experimenting to see if the same spices could clean dirty pond water. They did. Her tests soon turned into a winning science-fair project, which set the course for her professional life.

“For the most part, food-spoilage technologies involve toxic pads, refrigerated transport or a lot of plastic,” Shukla says. But “customers are really aware now. They are asking, ‘Hey, is that apple waxed? What is the wax?’”

To make FreshPaper, the company infuses a proprietary blend of bacteria-inhibiting spices into compostable, organic paper. The paper can be slipped into berry cartons, vegetable bins or bags of leafy greens. The exposure you get to the spices is similar to what you might get while walking through the spice aisle of a grocery store, Shukla explains.

Best of all, Shukla’s paper is inexpensive, compostable and safe for humans and the environment. “I had my grandmother in mind when I designed the technology,” Shukla says. “She never had a refrigerator.” The product is already sold in 180 countries.

For the FreshGlow Co., which has taken it slow and steady, scaling up is the goal: to bring its product to larger produce companies and food distributors around the world. “That was always my intention — to use the technology to reduce food waste across the supply chain,” Shukla says.

FreshPaper sheets are infused with organic spices and active botanicals. The FreshGlow Co. founder Kavita Shukla learned as a child that certain spices can inhibit bacteria growth. She turned her home remedy into a simple solution for prolonging the life of produce.

Data-driven Distribution

While entrepreneurs are recognizing the financial and humanitarian opportunities of extending food shelf life, Silicon Valley hasn’t really tapped into this huge revenue stream. Zest Labs in San Jose is trying to change that. The tech company is making the cold supply chain more efficient by accurately predicting the shelf life of produce as it moves around the country. It does this through the Internet of Things (IoT), the interconnection of computers and everyday objects through data sent and received via the Internet. These IoT sensors monitor the temperature of produce on each pallet, from field to the retail shelf.

Zest Labs uses pallet- by-pallet temperature data to help predict the rate of produce spoilage. “No other industry would accept one third of their production going to waste,” says Zest Labs CEO Peter Mehring in a video on the company’s website. Image courtesy Zest Labs.

“The largest impact on produce is temperature, harvesting conditions and variety of the product,” says Zest Labs’ Payne. “Pallets harvested first will vary from bottom to top,” he explains. “We can figure out that pallet A has this much shelf life, and pallet B has this much.” They do this by producing a Zest Intelligent Pallet Routing (ZIPR) code, which routes pallets with less freshness to the nearest location and those with a longer shelf life further afield.

Zest Labs has “removed the randomness of food distribution,” says Dr. Jean-Pierre Emond, a co-founder of The Illuminate Group and an expert on the cold chain. “For each pallet coming in, they now know exactly what to do with it.”

Zest Labs technology is enabling growers and retailers, who have never had this type of data, to profit more and waste less. They do this by reducing pre-harvest water, fertilizer and labor costs, as well as post-harvest costs for waste removal. Large companies like Costco have tapped into Zest Labs’ technology to help their growers, distributors and themselves.

“I never see anyone winning with food waste,” Emond says. The entire food supply chain stands to benefit from these new solutions.

To better understand the science behind Apeel’s product, check out this story from WIRED magazine.

To better understand the science behind Apeel’s product, check out this story from WIRED magazine.

Sell by? Use by? Why?

Food loss on the farm, in transit and at the retail store is significant. But the largest category is even closer: Nearly half of America’s food waste happens at home. A 2012 NRDC study found “the average American consumer wastes 10 times as much food as someone in Southeast Asia, up 50 percent from Americans in the 1970s.”

The food-waste problem is partly cultural. In the U.S., food is relatively inexpensive compared to other parts of the world. Thanks to busy lifestyles, we over-buy and under-plan. And inconsistent shelf-life food labeling confuses consumers and retailers. What does “sell by” and “best if used by” mean? Are foods past those dates actually spoiled? Often, they are not.

In 2013 the NRDC reported that food expiration date codes contribute considerably to the estimated 160 billion pounds of food trashed each year in the United States, “making food waste the single largest contributor of solid waste in the nation’s landfills.” Food expiration date codes are not federally regulated. They vary by state and are often arbitrary, providing false confidence in a food’s freshness or spoilage.

“There isn’t a rhyme or reason to how food codes are set,” says Michael Malmberg, chief operating officer of Daily Table, a nonprofit Boston-based grocery store that sources nearly expired food from local farms, distributors, grocery stores, restaurants and bakeries, and resells that food at affordable prices. “It’s set by the manufacturer or packager and can be done for marketing reasons — if they want to turn a product over faster.”

Doug Rauch, a former president of Trader Joe’s — and Malmberg’s boss — saw an opportunity to change perceptions of shelf life at the retail level. Rauch was well aware of how much perfectly good food was wasted by grocery stores due to confusing food labels. While a fellow at Harvard University, he also learned that food malnourishment meant not just “a deficit in calories; it was a deficit in nutrition, and supply chain issues,” Malmberg says. “(Doug) realized there is a need not only for access to food, but access to healthy food that’s affordable.” Out of that came the concept for Daily Table, which opened its doors in June 2015.

Rauch likes to think of his two grocery stores, located in Roxbury and Dorchester, Massachusetts, as the T.J. Maxx or Marshalls of the food world — where you can shop for quality products at reduced prices without the stigma that comes with visiting a food bank. This model, backed by the PepsiCo Foundation, the Kendall Foundation and the Robert Wood Johnson Foundation, recognizes the flexibility in food expiration codes.

“It’s all well and good to have healthy produce,” says Malmberg. “But if people get home from work and don’t have dinner on the table, they’re in trouble.” So Daily Table also set up an on-site kitchen and hired chefs to turn ugly produce or products that are not moving off the shelves quickly enough into affordable, nutritious, ready-to-cook and grab-n-go meals that cost the same price or less than nearby fast food. Daily Table hopes to open more stores because “the concept will be more effective at scale,” says Malmberg. “We are currently covering 65 percent of our expenses. We think with a third or fourth store, we can break even.”

Breaking even, when it comes to food waste, would be a big step in the right direction.

Daily Table in Massachusetts takes in food rejected by other retail outlets for aesthetic reasons. For example, an entire pallet of organic cauliflower heads that were deemed “unmarketable” due to a few brown spots were saved before they ended up in a dumpster. The DT team sorted and repackaged them for sale as raw produce and as part of their prepared foods offerings. Image courtesy Daily Table.

Books

Books

Podcasts

Podcasts

Film/TV

Film/TV