Food Movers: Keg Cycle

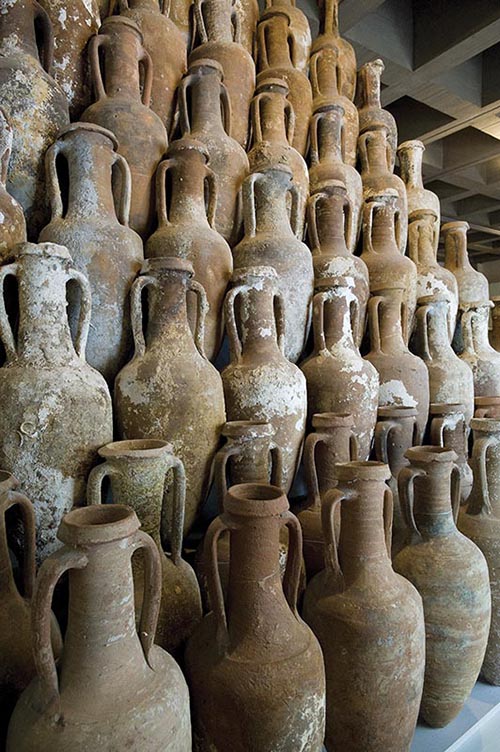

Few pieces of hardware are as synonymous with a good time as a keg. And while other carbonated fluids are stored in these aluminum or stainless steel tanks, when we hear the word keg, we think of one beverage: beer.

Nationwide, breweries opened at a rate of nearly three per day during 2017 — 997 in total — and each brewery has its own fleet of kegs. Each one of these vessels has a salmon-like lifecycle in which it leaves its homeland full of life and returns home depleted. Unlike a spent salmon, an empty keg can jump back in for another round. But like all too many migrating fish, many kegs never make it home. Of those 997 breweries that opened in 2017, 165 went belly up. For a company that’s barely covering its costs, keg loss can make the difference between a red or green bottom line for the year.

When a keg is filled at a brewery, it is ready to go out into the world and do its job dispensing beer to the people. A distributor facilitates its journey, which may include a retail outlet such as a bar, restaurant or liquor store — the first stop before its destination at a party by the lake or other #goodtimes. If all goes well, and everyone keeps their word, the empty keg will eventually return to its home brewery. If not, and the keg never makes it home, the brewery that owns it foots the bill.

An American-made stainless-steel keg can cost a brewery more than $100, and the average annual keg loss nationwide is about 6 percent, says Tim Cognata, business development director of the beer services company Satellite Logistics Group (SLG). This transformation from stainless steel to statistic ends up costing a lot more than the $30 deposit normally collected when the brewery lets a keg go. For a small brewer, he says, replacement costs for kegs can add up quickly and take a big bite out of the profit margin.

SLG offers a service called KegID, introduced in 2012, which uses scannable barcodes to keep track of a keg’s movements, including timestamps at various stops in the keg cycle and notes about maintenance and contents.

If a keg is not returned, services like KegID provide concrete data for tax-loss purposes. Even though breweries may lose more than 5 percent of its fleet of kegs, Cognata says, most breweries are writing off a mere 1 to 2 percent drop in keg numbers because they don’t have the documentation to prove greater losses. If breweries had tracking data for each keg, they could claim all of those lost vessels without worrying about facing a penalty for overclaiming, in the event of an audit.

The same data that allow a brewery to prove its loss to the IRS can also serve as evidence with which to confront a distributor for losing kegs. Sometimes a retailer collects a larger deposit than the brewery charges the retailer, which can be especially bad for keg recovery. Regardless of the reason a keg is lost, and whether or not it’s found, breweries are happy to be armed with the data KegID provides, says Cognata.

“KegID has an invoice function where you can bill a distributor for the residual value of a keg, minus the deposit,” Cognata explains. “Most distribution contracts state that the distributor is responsible for any lost assets. We provide the concrete data so that conversation can happen: ‘We sent you X number of kegs, and Y came back.’”

Thanks to that hard evidence, Cognata says, when distributors know a brewery partner uses KegID, kegs start coming back.

Other technologies are being deployed toward similar goals. A handful of well-to-do breweries are welding GPS transmitters to their kegs to track their every move — but it’s extremely expensive (think satellite phone versus cell phone). In 2009, New Belgium Brewery began attaching Radio Frequency Identification Devices (RFID) to its 100,000 kegs. RFID is a different way to keep track of information similar to what KegID stores.

“(RFID) lends itself to keeping track of whole pallets of cargo rather than individual kegs,” Cognata says. New Belgium has since moved from RFID to SLG’s tracking technology.

The ability to closely track these mobile assets adds up to big cost savings for brewers. Today, more than 200 breweries use KegID, from well-known national micro brands like Sierra Nevada to well-named niche labels like Moustache Brewing Company.

When the container is worth almost as much as the contents it holds, it pays to keep track.

Watch Ceiba’s building progress through a

Watch Ceiba’s building progress through a