An Art Tour of Food Logistics

If you want a new experience while visiting an art museum, try going as a food logistics nerd.

Recently, I had this pleasure at Boston’s Museum of Fine Arts, the home of such luminaries as John Singleton Copley and John Singer Sargent. The two ladies at the front desk, each sporting particularly colorful eyeglasses — one in flamingo pink and the other in cerulean blue — slowly warmed up to my request and began sketching a path through the museum on the printed floor plan. “Go to the Americas room and look for jars. Then go to the Classical Art rooms and see if you can find amphorae,” they offered, visibly surprised that they had discovered something.

For my part, I wanted to hunt down Winslow Homer’s images of fishermen lugging halibut.

Here’s what I found.

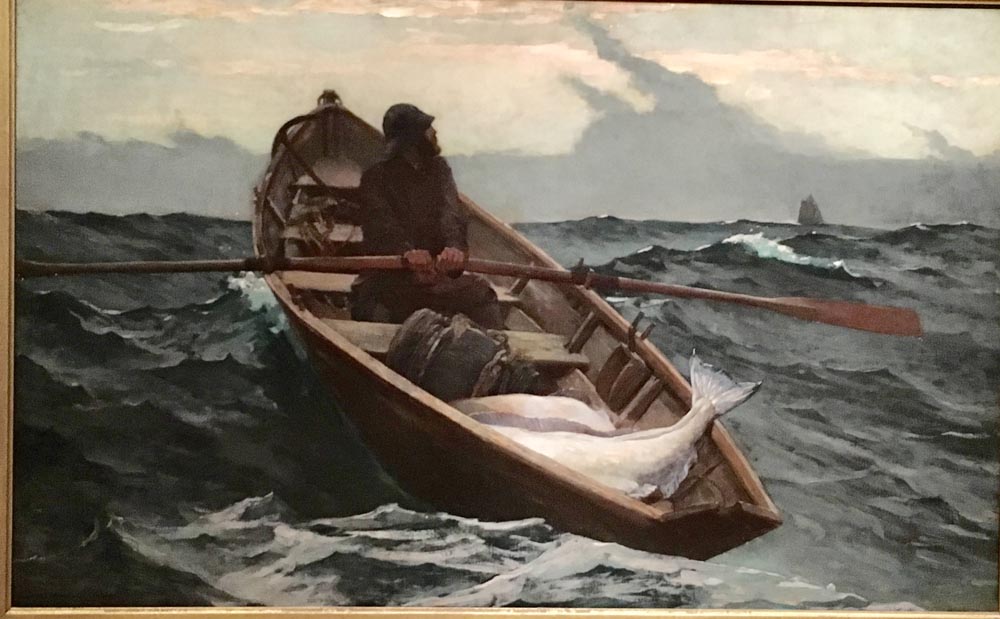

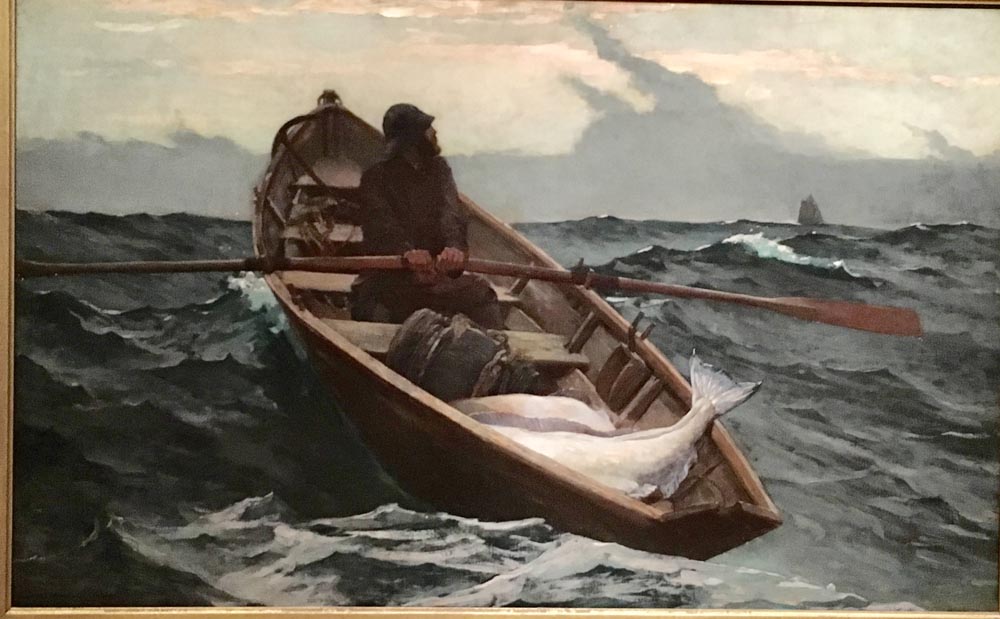

The Fog Warning, Winslow Homer

Winslow Homer’s The Fog Warning, is the dark, foreboding image of a solitary fisherman looking over his shoulder at the oncoming fog bank, his boat weighted down in the stern by two huge halibut. Does he make it home? There’s a schooner on the horizon in the distance. Does he know the ship? Does he reach them? His boat is a fishing dory, a flat-bottomed rowboat that was designed to carry large loads of fish caught at sea.

Salem Harbor, Fitz Henry Lane

Fitz Henry Lane, an American painter known for his ethereal use of light, lived in Gloucestershire, Massachusetts, where images of ships and the fishing industry surrounded him. Salem Harbor, painted in 1853, was the center of the China trade that brought not only silks but also tea from halfway around the world. Square-rigged schooners and other working boats fill the harbor, unloading cargo into the Salem warehouses.

Whaler in the Ice, Chopping Out, William Bradford

You can feel the chill of the Arctic wind in William Bradford’s Whaler in the Ice, Chopping Out. The black and white charcoal image illustrates the slow, cold journey whalers take as they hunt spermaceti and other whale oil to fuel American households and their cooking stoves.

The Wreck of Ancon, Loring Bay, Albert Bierstadt

Albert Bierstadt, the master of romantic, heroic American landscapes, recorded the demise of the ship Ancon, which was stranded on a ledge in Alaska with its cargo of canned salmon. This 1869 oil painting, The Wreck of the Ancon, Loring Bay, captures the fragility of 19th-century food logistics with ship’s cargo at risk of weather, ledges and pirates.

Greek Vessels

The rooms filled with Greek antiquities included numerous jars and amphorae that held food, water and wine for various purposes — some for rituals, others purely utilitarian. One two-handled amphora from the Archaic Period (540-520 BC) gleamed from one case, displaying figures and grapes all the way around its midsection. As with most Greek vessels, the surface tells an elaborate tale of gods and humans. On this amphora, you see Dionysus (the Greek god of the grape harvest and winemaking) drinking wine while satyrs make more. The amphora illustrates the process of winemaking, including each of the various steps between the vine and your plate. Other, less ornate amphorae transported oil and wine across the Mediterranean in ships’ holds.

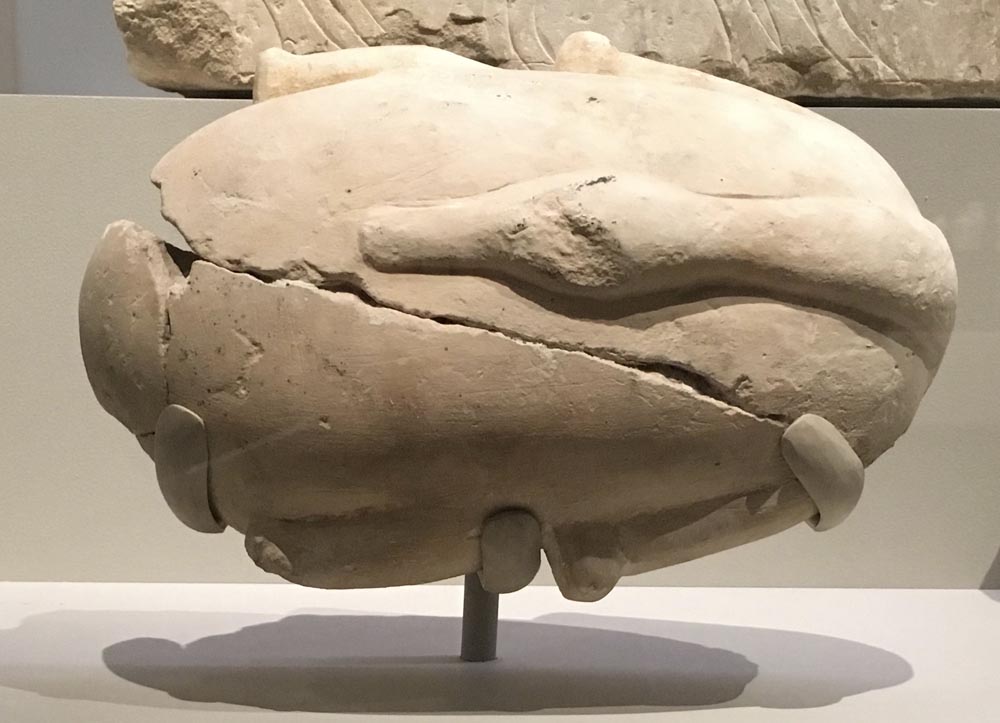

Food for the Dead

And finally, food transported to the dead is a food supply chain familiar to cultures that believe in an afterlife. The Egyptians assembled elaborate kits for those who departed from their world to the next. These stone containers, often depicting the food encapsulated within, contained the necessary sustenance to survive the next world. Called “food cases,” they were filled with provisions such as beef ribs and bread, sometimes wrapped in the same materials as the individual embalmed inside a sarcophagus. Notice that this one has a duck carved on the exterior, suggesting that a duck breast awaited the departed.

Imagining a museum as a repository of food logistics stories turned up some surprises and even more reminders that transporting food around the world has been going on at least since the Egyptians packed food for the afterlife. Whether in this life or the next, the movement of food can be a combination of art and science, utility and aesthetics. I can’t wait to visit another museum with food logistics goggles.

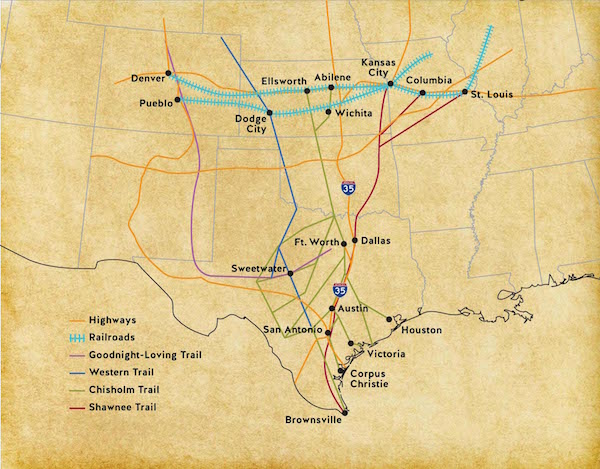

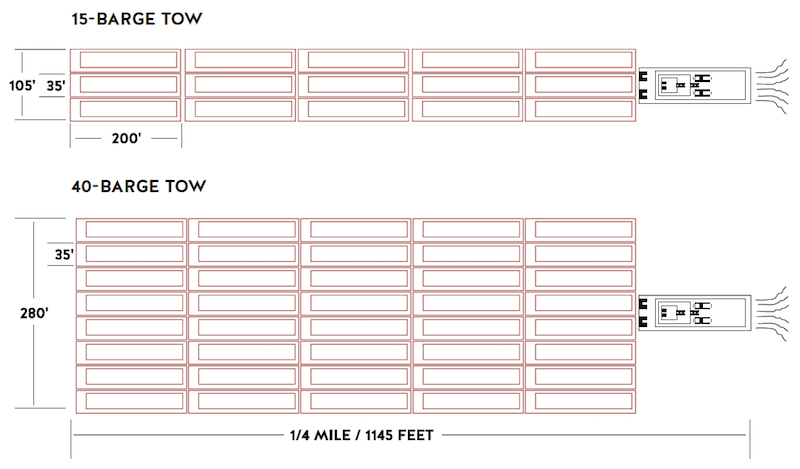

Chisholm Trail

Chisholm Trail